Dry Film Decoration

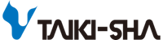

Taikisha’s dry decoration line transfers parts through a 6-step process to take a raw stamped or molded part and automatically decorate, finish, and inspect each part.The parts are first cleaned of any dirt or residue before the dry film is applied with a vacuum-pressure technology. After the film is set (and cured via UV or other process, if necessary based on the selected film), the excess film is automatically trimmed and removed. The part is then inspected for quality before being transported to the assembly process.

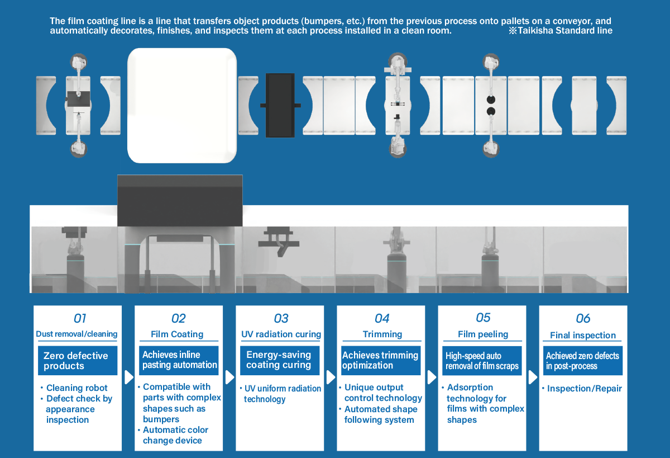

OMD Dry Film Line Process Overview

Taikisha’s dry decoration line transfers parts through a 6-step process to take a raw stamped or molded part and automatically decorate, finish, and inspect each part.

The parts are first cleaned of any dirt or residue before the dry film is applied with a vacuum-pressure technology. After the film is set (and cured via UV or other process, if necessary based on the selected film), the excess film is automatically trimmed and removed. The part is then inspected for quality before being transported to the assembly process.

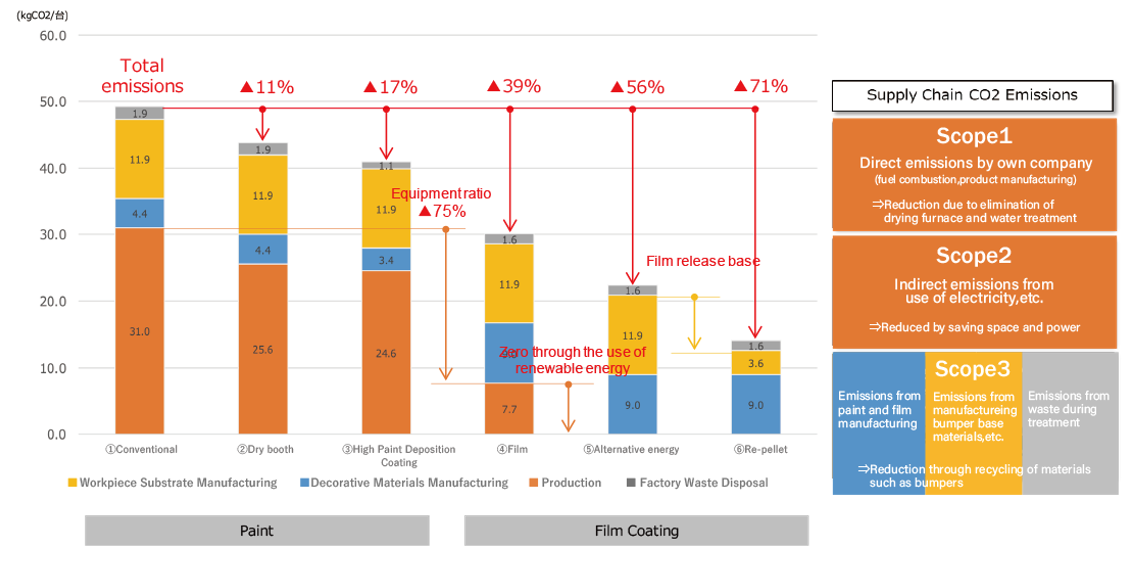

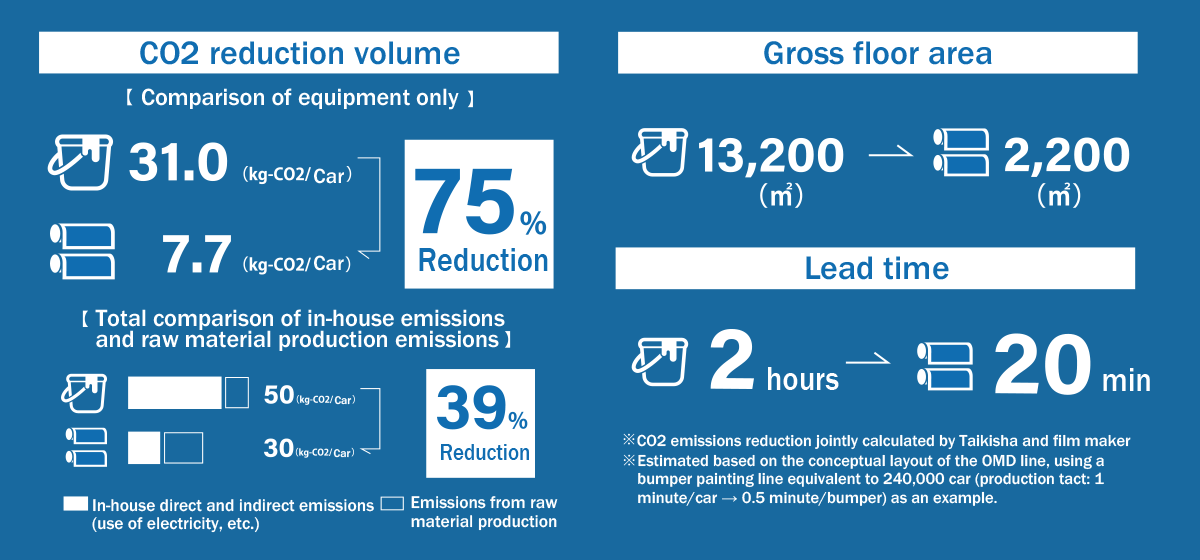

Comparison of CO2 Emissions per unit (by Scope 1, 2, & 3)

Object: 240,000 bumper/year (480,000 bumpers/Year)